This test campaign studied the performance of a microchannel heat exchanger developed by Reaction Engines. The heat exchanger transferred heat from a flow of ambient temperature helium to a separate flow of helium at -180°C (90K). This required AEL to provide two high-pressure helium supply lines, each with massflow …

Airborne Engineering Limited (AEL) have designed and successfully flown a demonstrator VTVL (vertical take-off, vertical landing) rocket vehicle. This vehicle, codenamed “Gyroc”, a shortening of “gyro-stabilised rocket”, is the result of an internal research and development project that has been under way at AEL for a few years at the …

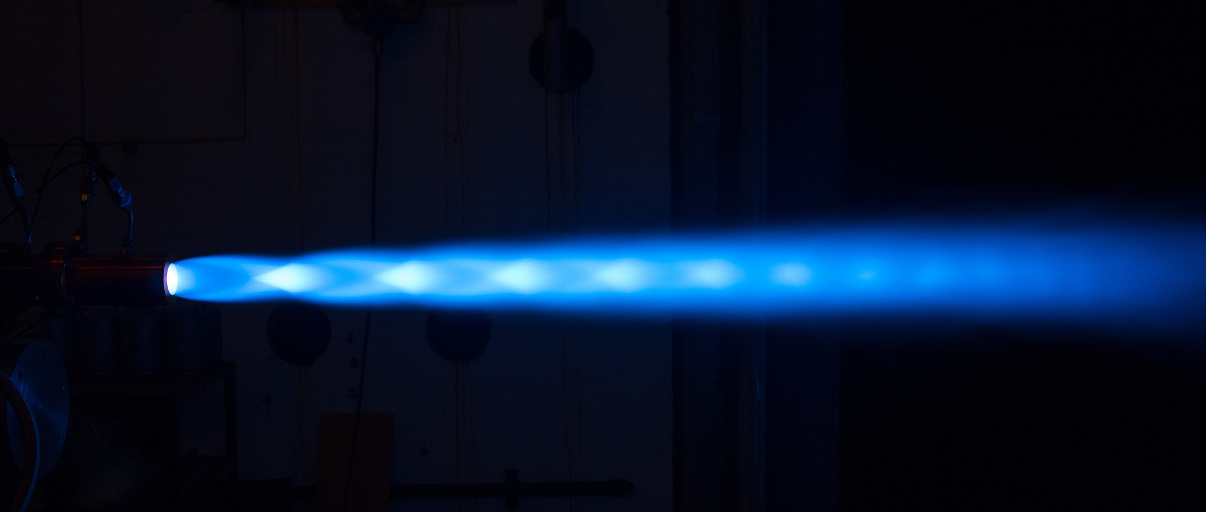

A collaboration between AEL and Impact Innovations GmbH studied the production of bimetallic combustion chambers using Cold Spray Additive Manufacture (CSAM). Impact Innovations GmbH are a leading cold-spray equipment manufacturer, based in Germany, and experts in the CSAM process. Representative demonstrator samples were designed by AEL suitable for CSAM manufacture …

This test campaign studied the performance of a heat exchanger with a letterbox-shaped cross section for a single module of the HX3 subsystem of Reaction Engines' SABRE engine. This required AEL to design a custom hot gas heat source, which was capable of providing partially combusted air with variable massflow …

This programme evaluated the suitability of using CuCrZr for additively manufacturing rocket engine combustion chambers, under a UKSA Pathfinder grant with maunfacturing partner 3T AM. Small test pieces were printed in CuCrZr to analyse the flow properties of various printed geometries. These included a full combustion chamber and injector head …

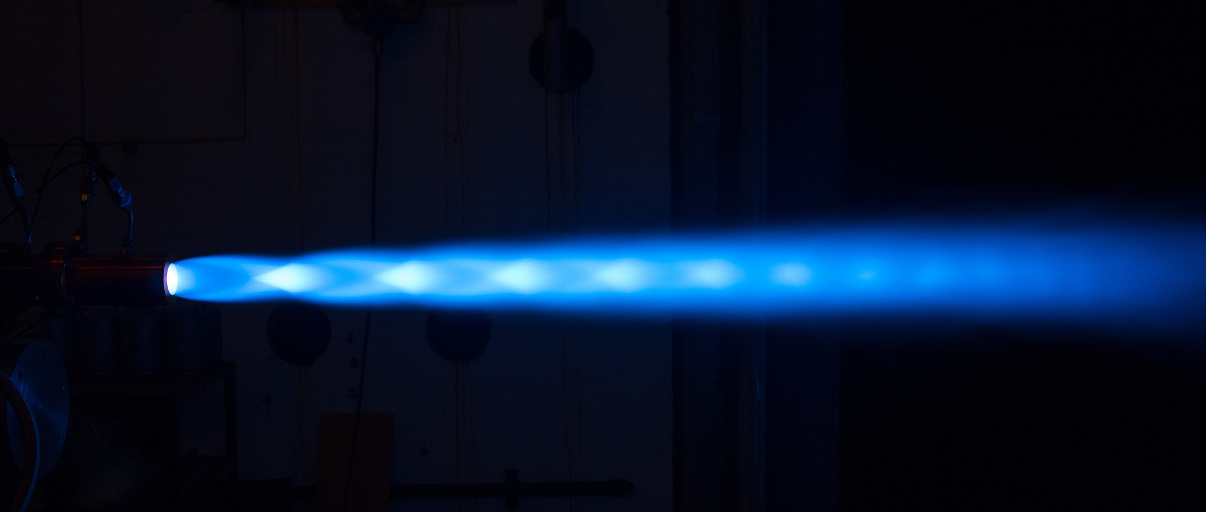

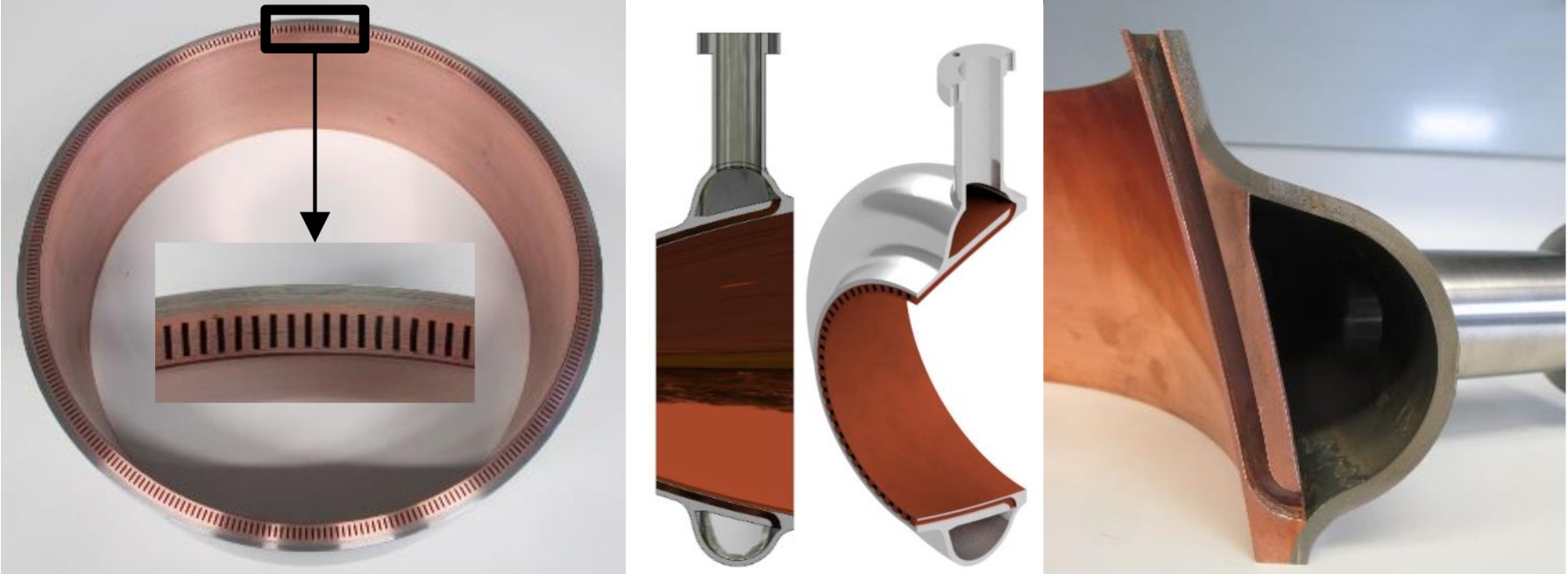

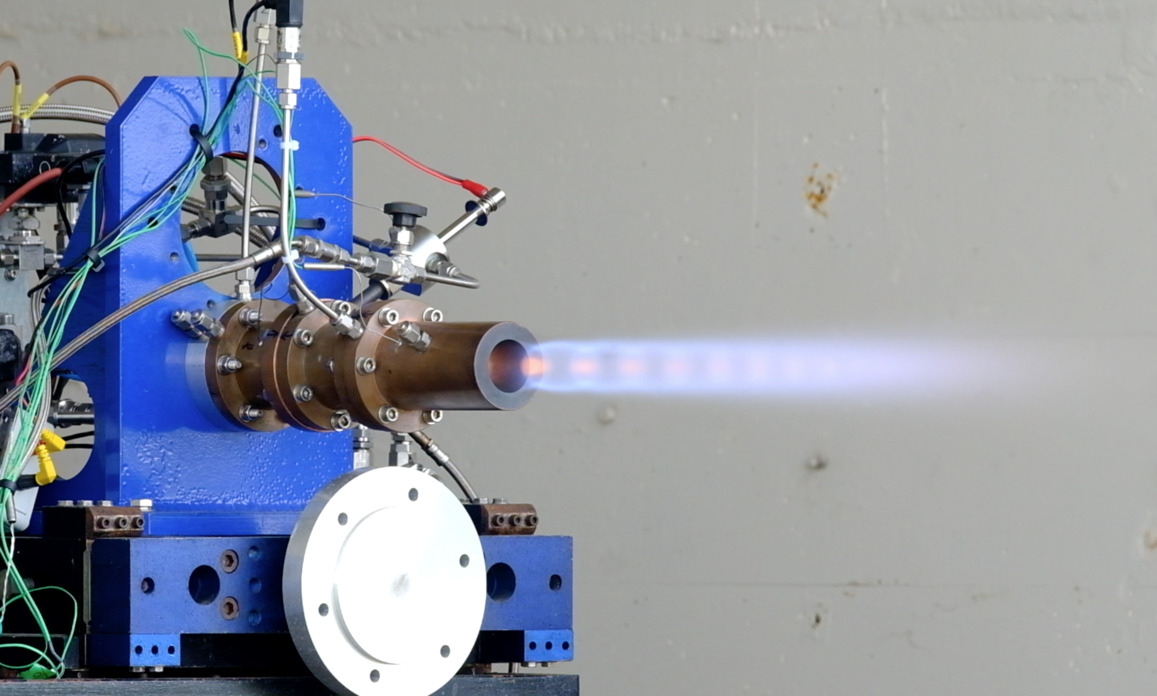

This test campaign studied the combustion performance of novel air-hydrogen injectors for the preburner of Reaction Engines SABRE engine. The subscale testing involved providing two air feeds (<1kg/s) and two hydrogen feeds (<5g/s), each of which required closed loop feedback control of massflow. Constant massflow profiles were used …

As part of a global drive to move towards less toxic propellants, Nitrous Oxide Fuel Blends (NOFB) have been identified as a potential monopropellant to replace hydrazine. These have high performance and the potential to be long term storable, but little is known about their combustion performance or long-term storability …

The Stoic engine was designed as part of the Advanced Nozzle programme by Reaction Engines under ESA funding. The Stoic engine has many subscale features of REL Sabre engine concept, most importantly that it has two combustion chambers for both air-breathing and rocket modes, and the ability to change between …

If rocket propellants can be made on Mars then huge savings can be made in vehicle size for return missions. This UKSA funded programme studied the combustion performance of various propellants that could be made in-situ on Mars, and studied the performance of the injection system. Propellants included oxygen, carbon …

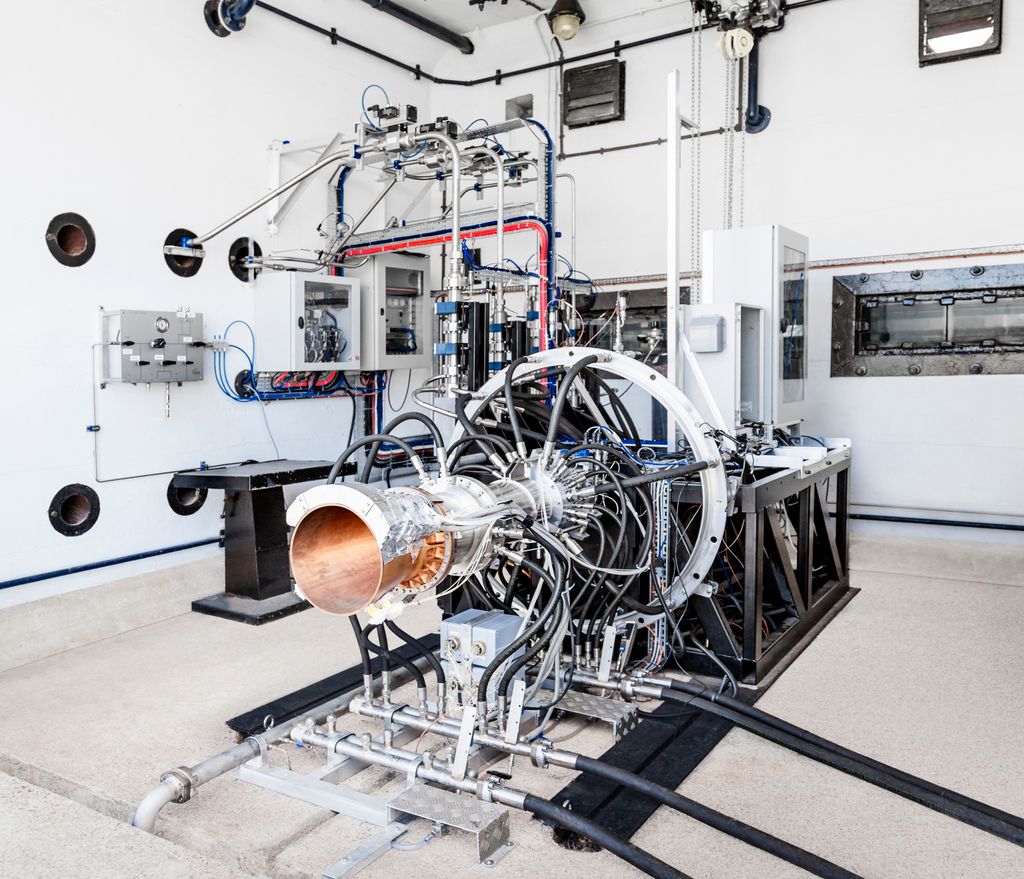

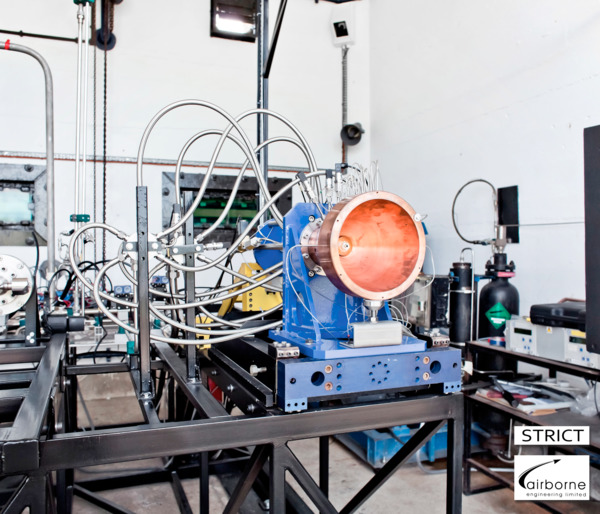

The STRICT engine evaluated the altitude compensating performance of an expansion-deflection nozzle using hydrogen and air propellants. This was a direct follow-on from the STERN programme, but with higher massflows and total thrust. It required careful measurement and control of the propellant massflows and high-speed measurement of nozzle wall-pressures to …

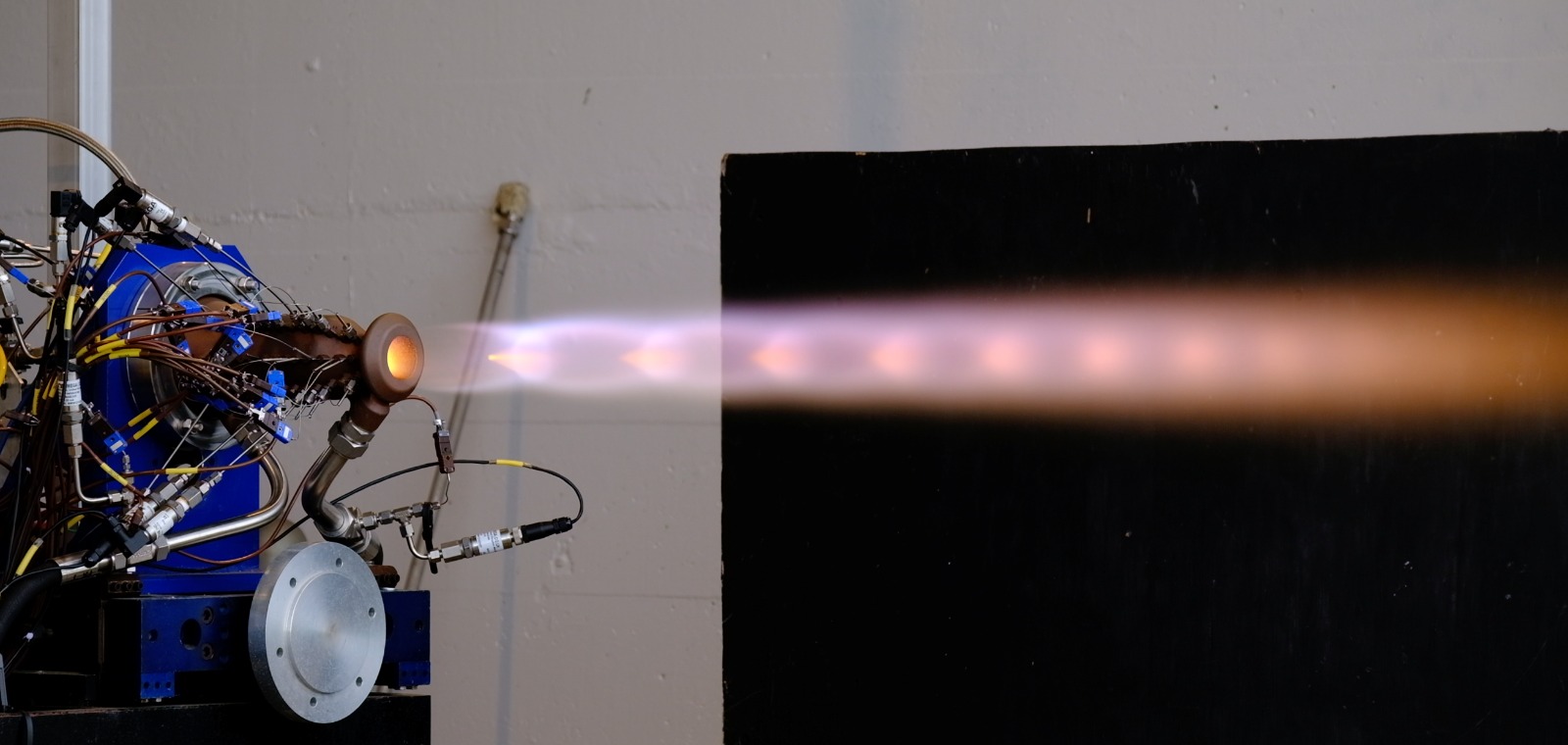

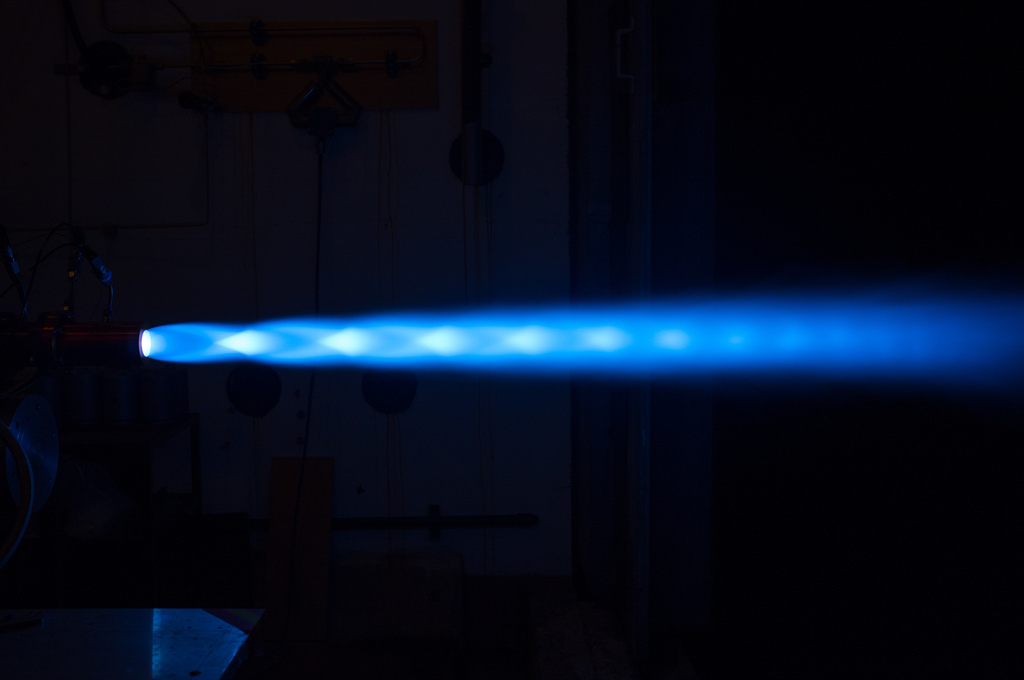

The Static Test Expansion-deflection Rocket Nozzle (Stern) engine was a 5kN gaseous hydrogen-air rocket engine with an expansion-deflection nozzle and a copper heat-sink chamber. It was tested in both cold and hot flow conditions. The experiments were designed to test the altitude-compensating performance of a nozzle with this geometry, which …